Sticker Manufacturing Process at Sharma Labels

Sticker Manufacturing Process at Sharma Labels

- Home

- EP Metal Stickers

- UV DTF Stickers

- Blog

- Contact us

- Collection Store Sticker

- Sticker Manufacturer

- UV DTF Stickers Manufacturer

- UV DTF Stickers Online

- EP Metal Stickers Manufacturer

- Sticker Manufacturing Process

- Corporate Gift stickers Delhi NCR

- Corporate Gift stickers Mumbai

- Corporate Gift stickers Bangalore

- Corporate Gift stickers kolkata

- Corporate Gift stickers Chennai

- Corporate Gift stickers Ahmedabad

- Self upload

At Sharma Labels, sticker manufacturing is not just printing. It is a controlled process that focuses on durability, finish, and consistency. Our sticker manufacturing process is designed to meet commercial branding standards for businesses across India.

From material selection to final quality checks, every step is handled in-house to ensure reliable results for bulk and custom orders.

Understanding the Importance of a Professional Manufacturing Process

A well-defined manufacturing process ensures:

Consistent quality across batches

Strong adhesion and long product life

Accurate color reproduction

Reduced rejection in bulk orders

This is especially important for businesses that rely on packaging and branding to build customer trust.

Step-by-Step

Sticker Manufacturing Process

Step 1: Requirement Analysis & Consultation

We begin by understanding:

Product type and surface

Usage conditions (water, heat, handling)

Quantity and timeline

Branding expectations

Based on this, we recommend the most suitable sticker type.

Step 2: Design Review & Print Preparation

If artwork is provided, we verify:

Size and layout

Color accuracy

Text clarity

If required, our team assists with basic design alignment to ensure print-ready output.

Step 3: Material Selection

The right material is selected based on application:

UV DTF films for curved surfaces and premium finish

Metal base films for EP metal stickers

Vinyl materials for outdoor and heavy-use applications

Adhesive selection is done to match the product surface.

Step 4: Printing & Curing

We use commercial-grade printing technologies:

UV printing for UV DTF stickers

Electroplating processes for EP metal stickers

Each print is cured and stabilized to ensure durability and finish consistency.

Step 5: Cutting, Finishing & Detailing

After printing:

Stickers are cut to exact shapes and sizes

Edges are checked for clean finish

Sheets or individual formats are prepared

This step ensures visual appeal and ease of application.

Step 6: Quality Inspection & Testing

Every batch undergoes:

Adhesion testing

Visual inspection

Finish consistency checks

Only approved stickers move to packaging.

Step 7: Packing & Dispatch

Stickers are packed securely to prevent damage during transit.

We dispatch orders across India with proper tracking and documentation.

Manufacturing Capabilities at Sharma Labels

Our facility supports:

Low MOQ for startups

Bulk manufacturing for large brands

Custom sizes and shapes

Repeat orders with consistent output

We maintain records to ensure repeat batches match previous quality.

Why In-House Manufacturing Matters

In-house manufacturing allows us to:

Maintain quality control

Reduce dependency on third parties

Offer better pricing

Handle urgent and custom orders

This is why brands prefer working directly with a manufacturer.

Industries We Serve Through Our Manufacturing Process

Our manufacturing process supports industries such as:

Food and beverage

Cosmetics and personal care

Electronics and appliances

Gifting and packaging

Small businesses and startups

Each industry has different durability needs, which our process accommodates.

Frequently Asked Questions

Is the sticker manufacturing process different for each sticker type?

Yes. UV DTF, EP metal, and vinyl stickers each follow a specific process based on material and usage.

Do you manufacture stickers in-house?

Yes. All key manufacturing steps are handled in-house.

Can you handle bulk orders with consistent quality?

Yes. Our process is designed to maintain consistency across bulk production.

Do you provide samples before bulk production?

Yes. Samples or previews are provided wherever required.

POPULAR SEARCHES

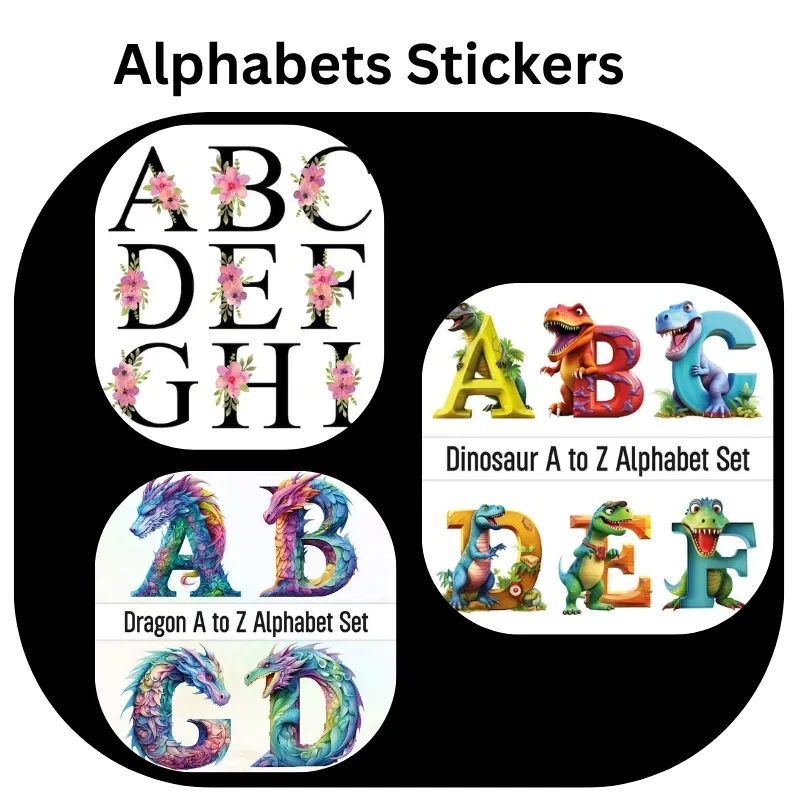

EP Metal Stickers | Uv Dtf Stickers | Feather Stickers | Birds Stickers | Cartoon Stickers | Evil Eye Stickers | Mandala Art Stickers Rakhi Stickers | Religious Stickers | Festivals Stickers | Shukrana Guru Ji Stickers | Alphabets Stickers | Butterfly Stickers | Coffee Stickers | Ladies Face Stickers | Mantra Stickers | Quotes Stickers | Resin Art Stickers | Valentines Stickers | Islamic Stickers | Artist Collection Stickers | Diwali Stickers